Seal Concrete Paths and Walls to Prevent Lime Leaching: A Practical, Step-by-Step List 1) Why sealing matters: stop lime leaching before it ruins your surfaces Have you noticed white crusts, powdery streaks, or a dusty surface on concrete paths and retain…

1) Why sealing matters: stop lime leaching before it ruins your surfaces

Have you noticed white crusts, powdery streaks, or a dusty surface on concrete paths and retaining walls? Those are signs of lime leaching and efflorescence - water carrying soluble calcium and salts from inside the concrete to the surface. Why does this matter? Beyond the unsightly look, ongoing leaching signals persistent moisture movement. Moisture decays embedded steel, encourages freeze-thaw cloudy window fix damage, and reduces the life of coatings and pavers.

What happens if you ignore it? You may recoat multiple times only to see the same white deposits return. The right sealer reduces water entry or controls where moisture escapes, cutting off the route that carries dissolved lime. But sealing is not a single-product decision - it’s a system: diagnose the moisture path, choose a compatible chemistry, and apply in a way that allows the structure to breathe where it must. In short, sealing without diagnosis can trap moisture and make things worse. Do you know where the water is coming from? How long has the concrete been exposed? Asking these questions up front saves time and money.

2) Choose the right sealer: how chemistry affects lime control and breathabilityNot all sealers do the same job. Which chemistry is best depends on use, exposure, and whether the concrete is horizontal or vertical. Here are common options and when to use them:

Silanes/siloxanes (penetrating water repellents) - Excellent for outdoor concrete and masonry where breathability matters. They penetrate and form a hydrophobic barrier that reduces water absorption while allowing vapor to pass. Ideal for vertical walls and exposed paths. Expect coverage roughly 100-200 sq ft/gal depending on porosity. Acrylics (film-forming) - Good for aesthetics and color enhancement on horizontal surfaces. They block surface water but are less breathable than silanes. Avoid acrylics on walls where trapped moisture is likely. Epoxy/polyurethane coatings - Durable and chemical resistant, suitable for high traffic or industrial areas. Many are not vapor-permeable and can trap salts unless a moisture mitigation system is used first. Silicate densifiers - React chemically to strengthen and densify the surface. They reduce dusting and improve abrasion resistance. They do not repel water like silanes but reduce porosity and can slow leaching. Crystalline waterproofing - A reactive treatment that plugs capillaries and can self-seal hairline cracks as moisture moves through. Strong option for below-grade walls and structures constantly exposed to groundwater or salts.Which should you pick for a garden path versus a retaining wall? For a sun-exposed garden path, a silane or siloxane gives long-term water repellency without gloss. For a damp retaining wall with hydrostatic pressure, combine crystalline treatment with external drainage or a breathable silane depending on access and budget. Have you tested the concrete’s vapor transmission yet? That test often drives the sealer choice.

3) Prepare the concrete properly: diagnose salts, make repairs, and test moistureSealing over a dirty, cracked, or salt-saturated surface is like painting over rust. Proper preparation reduces failures. Start by asking: is the white residue surface efflorescence, or is moisture migrating from inside? Simple tests help:

Scrape and wipe: remove loose salts with a stiff brush, then dampen the area. If the white reappears while the surface dries, efflorescence is active. Solubility test: wipe suspected salts with distilled water on a cloth. If the residue dissolves, it’s soluble salts and indicates active leaching. Moisture tests: perform an in-situ relative humidity test (ASTM F2170) or a calcium chloride test (ASTM F1869). These tell you if vapor pressures are too high for non-breathable coatings. Surface cleaning options: mechanical removal with wire brush or pressure washer (low pressure, 1000-1500 psi for most concrete) or chemical cleaners for stubborn salts. If using acid to remove heavy efflorescence, use diluted muriatic acid carefully, rinse thoroughly, and neutralize, or hire a professional.Repair cracks and spalls before sealing. Use compatible cementitious patching compounds or polymer-modified mortars on vertical faces. For hairline cracks, consider injecting epoxy or using crystalline products that help self-heal. Don’t forget drainage: poor grading or blocked weep holes will keep delivering moisture and salts. Can you improve drainage before sealing? Often, a simple fix like re-grading or adding a gravel strip makes the sealer far more effective.

4) Application methods that actually work: timing, tools, and common mistakesApplication is as important as product choice. What tool and schedule will give you the best chance of long-term success?

Timing and weather: Apply sealers when surface and ambient temperatures are in the product’s recommended range, typically 50-90°F. Avoid application if rain is expected within 24-48 hours or if dew will form overnight. Low humidity slows cure for some chemistries; high humidity may cause blushing on films. Tools: Use a pump sprayer with a fan tip for penetrating silanes to ensure even wetting. Rollers and brushes are good for acrylics and densifiers. For epoxies and polyurethanes, use short-nap rollers designed for high-solids coatings and follow specified spread rates. Coverage and multiple coats: Follow manufacturer coverage rates. Penetrating sealers usually require one generous coat; film-forming products often need two thin coats. Over-application leads to pooling and runs on vertical faces, while under-application reduces protection. Common mistakes: Sealing onto damp surfaces, failing to remove salts, and using non-breathable coatings on moisture-prone concrete. Have you allowed adequate dry time after cleaning and repairs? Moist concrete will trap moisture and defeat many coatings.For large projects, mock-up areas are invaluable. Apply the selected sealer in a small test patch, watch for efflorescence return over a few months, and confirm appearance and slip resistance. This prevents costly failures on the whole job.

5) Advanced treatments: crystalline systems, silicate densifiers, and combining methodsWhen ordinary sealers aren’t enough, consider layered or reactive approaches. What advanced options can significantly reduce lime leaching?

Crystalline waterproofing: Often applied as a slurry or integrated into the concrete mix, crystalline products react with water and unhydrated cement to form insoluble crystals that block capillaries. They work well for below-grade walls and structures subject to hydrostatic pressure. Example: concrete basement walls where exterior access is limited. Silicate densifiers: Sodium or lithium silicates penetrate and react to form additional calcium silicate hydrate, densifying the cover and reducing dusting. This reduces capillary flow and slows leaching. Because densifiers often harden the surface, they pair well under polished finishes or thin coatings. Combine for best results: In some cases, a crystalline treatment for the bulk of the concrete and a silane topcoat for exterior water repellency give complementary benefits: crystal plugs inside the concrete, silane protects from surface wetting. For heavy traffic or aesthetic demands, a densifier plus a breathable stain or topical finish might be best. Monitoring and instrumentation: For critical structures, install humidity sensors or salt monitoring points to track whether leaching continues after treatment. How will you verify the system is working six months from now?Choosing combinations requires attention to compatibility. Some densifiers leave salts that interfere with penetrating silanes. Always check technical data sheets and test small areas first.

6) Maintain and clean without making the problem worse: what to use and what to avoidMaintenance is where many projects fail. Regular inspection and gentle cleaning extend sealer life and catch problems early. What cleaning methods preserve the sealer while removing deposits?

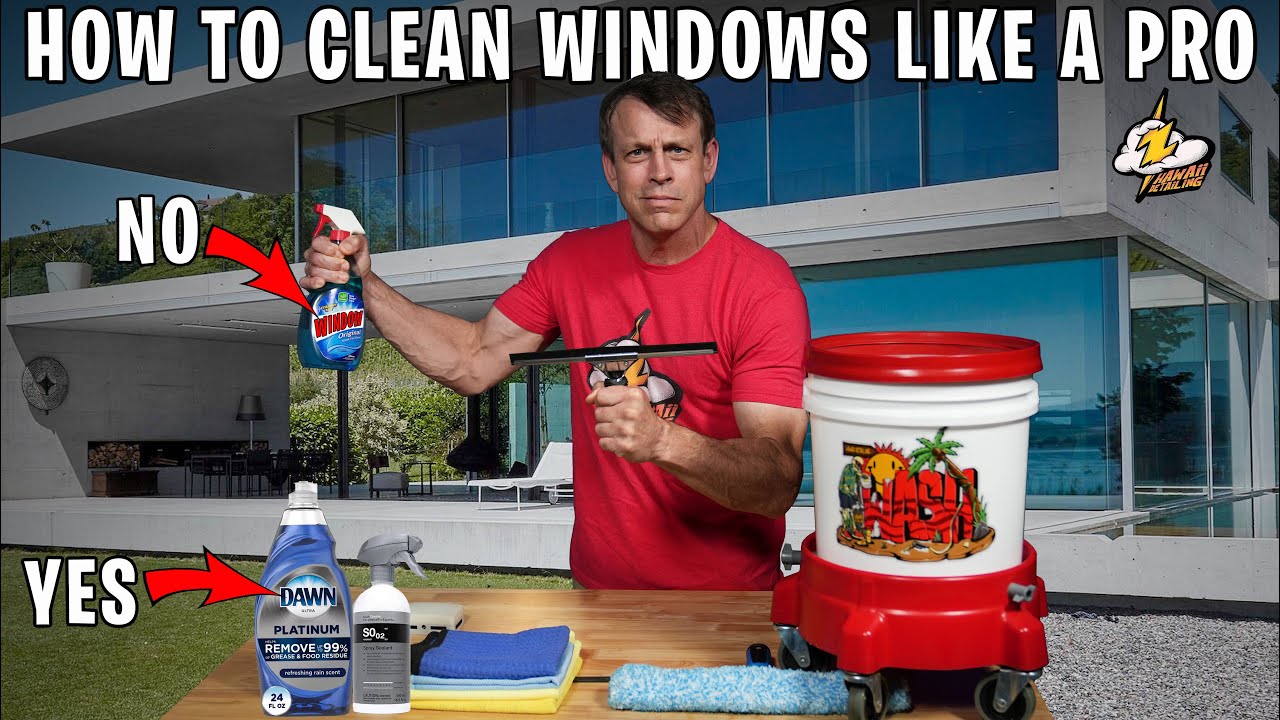

Preferred cleaners: Use pH-neutral concrete cleaners or mild detergents for routine cleaning. Enzyme-based cleaners can help with organic staining without affecting most sealers. For heavy soiling, low-pressure power washing (1000-2000 psi depending on surface) is effective when used at a shallow angle to avoid abrasion. Rinse thoroughly and allow to dry before re-applying any sealer. Avoid ammonia and alcohol-based cleaners: Why? Ammonia can raise surface pH and react with certain sealers and pigments, causing discoloration or reducing adhesion. Alcohols evaporate quickly and may strip some film-forming sealers or interfere with curing if used before final cure. Both can disturb the sealer film or the chemical balance of reactive treatments. Instead, read the sealer’s maintenance instructions and stick to recommended products. Dealing with efflorescence return: If salts reappear, remove them mechanically or with a salt-removal product formulated for masonry. For stubborn residues, a brief, controlled acid wash can work, but only after drying and neutralizing, and never on crystalline-treated surfaces without guidance. After removing salts, identify the moisture source and repair it before resealing. Inspection cadence: Check paths and walls seasonally. Look for cracking, pooling water, or loss of water repellency (test by sprinkling water - if it beads, repellency remains). Reapply penetrating repellents every 3-7 years depending on product and exposure; film-forming coatings may need recoating more often.Are you scheduling inspections and keeping a simple maintenance log? A little preventive care prevents major repair costs later.

Ready for a practical timeline? Here’s a focused 30-day plan you can follow. Each step balances testing, repair, and application so you don’t seal prematurely.

Day 1-3 - Inspect and document - Walk every area, photograph white deposits, cracks, pooling, and drainage problems. Ask: where is water entering or collecting? Day 4-7 - Test moisture and salts - Conduct an RH test (ASTM F2170) or calcium chloride test (ASTM F1869). Do a simple solubility test on visible salts. If RH or MVER is high, plan for breathable systems or moisture mitigation. Day 8-12 - Clean and remove salts - Brush, low-pressure wash, or use a recommended salt remover. For heavy deposits, consider a professional acid wash with neutralization. Allow thorough drying. Day 13-17 - Make repairs - Patch spalls, seal active cracks, improve grading or drainage where possible. Install or clear weep holes and gutters if relevant. Day 18-21 - Select products and test - Choose a sealer system based on tests: silane/siloxane for most exteriors, crystalline for problematic moisture, densifier for wear. Apply test patches and monitor for 7-10 days. Day 22-26 - Apply sealer - Follow manufacturer instructions: correct temp, coverage, and tools. Apply evenly and avoid puddling on verticals. Day 27-30 - Verify and document - Check bead behavior, adhesion on film-forming products, and any immediate return of salts. Record product names, batch numbers, coverage, and photos. Schedule a 6-month follow-up check. Comprehensive summaryPreventing lime leaching is not about a single cleaner or a quick seal. It’s a process of diagnosing moisture and salt movement, choosing a sealer system that matches exposure and vapor needs, preparing the substrate, applying correctly, and maintaining intelligently. Avoid common mistakes like sealing over damp concrete or using ammonia and alcohol-based cleaners that can harm coatings. Consider advanced options—crystalline systems and silicate densifiers—when plain repellents won’t cut it. Finally, small actions like improving drainage and scheduling seasonal inspections produce outsized benefits.

Which step will you take this week: test moisture, fix drainage, or trial a sealer patch? Pick one, and you’ll be on your way to stopping lime leaching for good.